Biodiesel

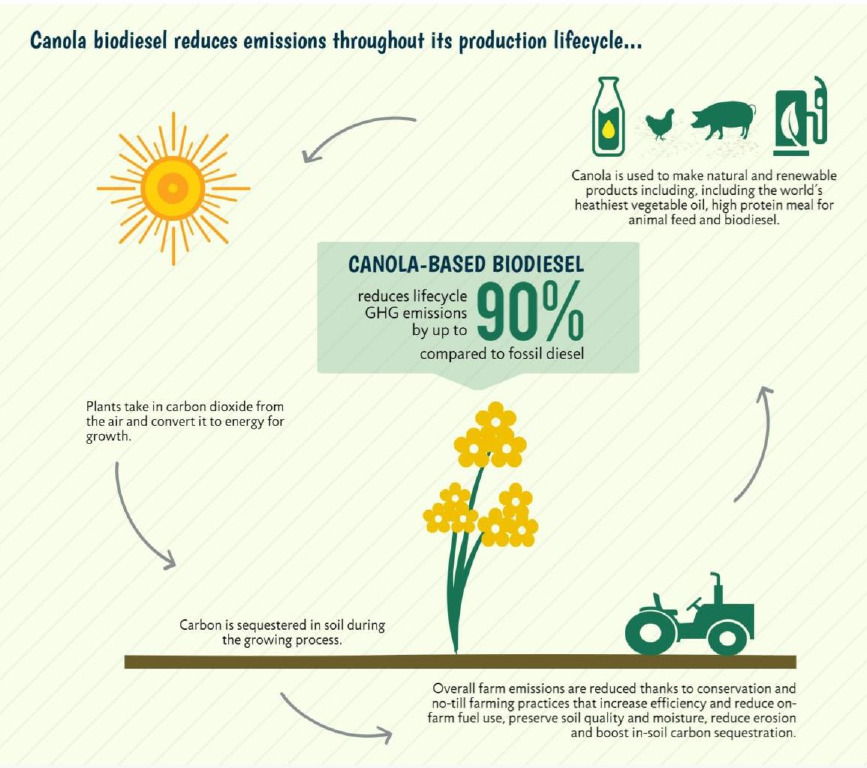

Canola can be processed into low-carbon biofuels, namely biodiesel but also renewable diesel and aviation fuel. It can also be utilized at petroleum refineries to lower the greenhouse gas (GHG) emissions of transportation fuels. These biofuels are made from canola oil, a natural and renewable resource. They are cleaner-burning alternative to petroleum fuels that can replace or be blended with diesel fuel for use in on-road vehicles, including municipal fleets to long-haul trucks, and off-road equipment used in agriculture and other industries.

Biodiesel is an alternative fuel made from renewable sources, such as canola oil and recycled cooking oils, that is non-toxic, biodegradable and renewable unlike petroleum diesel. It can be used in regular diesel engines with little or no modification, even in jet fuel. Canola oil meets the 50 percent greenhouse gas reduction requirement of the U.S. Environmental Protection Agency (EPA) as a raw material (feedstock) for biodiesel production under the Renewable Fuel Standard as well as feedstock requirements in Canada and the European Union.

Canola biodiesel is much more environment-friendly than petroleum (fossil diesel), lowering greenhouse gas emissions by up to 90 percent and not having a catastrophic effect if spilled. Specifically, biodiesel reduces emissions of carbon monoxide, particulate matter and sulfates as well as hydro-carbon and toxic air pollutants. In addition, biodiesel produced in the United States can reduce dependence on foreign oil and put money back into the rural economy.

Source: Canola Council of Canada

Source: Canola Council of Canada

Canola oil is one of the most effective and efficient sources for biodiesel with excellent cold-flow properties; what’s good for the heart is also good for the engine due to canola oil’s low saturated fat content. Plus, canola seed yields about 45 percent oil when crushed compared to only 18 percent for soybeans, the most common biodiesel feedstock. As a result, the U.S. Canola Association has a reciprocal board seat with the National Biodiesel Board.

Canola oil is made into biodiesel through a refinery process called transesterification. The oil is mixed with alcohol to remove glycerin, which can be used in skin creams, soaps and other personal care products. Crushed seeds are used in animal feed, providing a great source of protein. The entire canola plant is used when producing biodiesel so nothing goes to waste.

Biodiesel in its pure form is known as B100 or “neat,” but it is more commonly blended with conventional diesel, namely B5 (5 percent biodiesel and 95 percent diesel) and B20 (20 percent biodiesel and 80 percent diesel). Biodiesel is registered with the EPA and legal for use at any blend level in highway and non-road diesel vehicles. Biodiesel-run vehicles have similar horsepower and torque as those running on conventional diesel. Biodiesel allows for better engine performance and lubrication, but does have a small decrease in fuel economy (2-8 percent).

Today, about 600 fleets nationwide use biodiesel blends in their diesel engines, according to the EPA, and biodiesel is available in various blends at roughly 700 locations across the United States. A station locator is available online.